Specifications

Explanations of terms in columns can be found below the tables. In case of any questions feel free to contact us via e-mail at info [at] mastrant.com.

Mastrant CLASSIC

| Product & size |

Size [inch] |

Diameter [mm] |

Strength [daN, ~kg] |

Safe working load [daN, ~kg] |

Weight [g/m] |

Elongation [%] |

Remark | Price; [~100m] |

Variants |

|---|---|---|---|---|---|---|---|---|---|

| P 2 | 1/16 | 1.6 | 100 | 30 | 2 | 3.3 | black, blue dots | 20,00 € |

|

| C 3+ | 9/64 | 3.5 | 300 | 90 | 11.2 | 2.9 | camouflage | 49,00 € |

|

| Q 6 | 1/4 | 6.1 | 730 | 220 | 28.5 | 3.2 | black, gray dots | 102,00 € |

|

| R 2 | 1/16 | 1.6 | 100 | 30 | 2 | 3.3 | yellow, black dots | 22,00 € |

|

| P 3 | 1/8 | 2.6 | 200 | 60 | 5.3 | 3 | black, blue dots | 28,00 € |

|

| R 3 | 1/8 | 2.6 | 200 | 60 | 5.3 | 3 | yellow, black dots | 32,00 € |

|

| C 6 | 1/4 | 6.4 | 850 | 255 | 33.4 | 2.9 | camouflage | 124,00 € |

|

| Q 8 | 5/16 | 8.3 | 1700 | 510 | 45 | 3.4 | black, gray dots | 134,00 € |

|

| R 5 | 3/16 | 4.9 | 540 | 162 | 20.3 | 3 | yellow, black dots | 81,00 € |

|

| P 3+ | 9/64 | 3.5 | 300 | 90 | 11.2 | 2.9 | black, blue dots | 38,00 € |

|

| Q 11 | 7/16 | 11.2 | 2780 | 830 | 78 | 4.6 | black, gray dots | 193,00 € |

|

| P 4 | 5/32 | 4.4 | 440 | 132 | 15.3 | 3 | black, blue dots | 45,00 € |

|

| Q 14 | 9/16 | 13.5 | 3230 | 970 | 107 | 4.7 | black, gray dots | 263,00 € |

|

| O 5 | 3/16 | 5.8 | 540 | 162 | 20.3 | 3 | orange, reflective | 34,00 € |

|

| P 5 | 3/16 | 4.9 | 540 | 162 | 20.3 | 2.9 | black, blue dots | 66,00 € |

|

| S 6 | 1/4 | 6.1 | 730 | 220 | 29 | 3.2 | gray, reflective | 124,00 € |

|

Mastrant PREMIUM

| Product & size |

Size [inch] |

Diameter [mm] |

Strength [daN, ~kg] |

Safe working load [daN, ~kg] |

Weight [g/m] |

Elongation [%] |

Price; [~100m] |

Variants |

|---|---|---|---|---|---|---|---|---|

| M 1 | 3/64 | 1.3 | 100 | 30 | 1.3 | 0.6 | 40,00 € |

|

| M 2 | 3/32 | 2.2 | 220 | 66 | 4 | 1.0 | 47,00 € |

|

| M 3 | 1/8 | 3.2 | 390 | 117 | 7 | 1.0 | 78,00 € |

|

| M 4 | 5/32 | 3.9 | 900 | 270 | 11.4 | 0.8 | 156,00 € |

|

| M 5 | 3/16 | 5.2 | 1200 | 360 | 21.3 | 1.2 | 241,00 € |

|

| M 6 | 1/4 | 6.4 | 1850 | 555 | 32.3 | 1.0 | 300,00 € |

|

| M 8 | 5/16" | 7.9 | 2600 | 780 | 45.4 | 0.9 | 427,00 € |

|

| M 10 | 3/8 | 10.7 | 3850 | 1155 | 82 | 0.9 | 739,00 € |

|

| M 12 | 1/2 | 11.9 | 5500 | 1650 | 100.6 | 1.0 | 1.049,00 € |

|

HMPE ropes

| Product & size |

Size [inch] |

Diameter [mm] |

Strength [daN, ~kg] |

Safe working load [daN, ~kg] |

Weight [g/m] |

Elongation [%] |

Price; [~100m] |

Variants |

|---|---|---|---|---|---|---|---|---|

| D-F3 2 | 3/32 | 2 | 340 | 102 | 2.5 | 0.5 | 74,00 € |

|

| D-F3 3 | 1/8 | 3 | 880 | 264 | 4.6 | 0.5 | 93,00 € |

|

| D-F3 4 | 5/32 | 4 | 1500 | 450 | 8.4 | 0.5 | 133,00 € |

|

| D-F3 5 | 3/16 | 5 | 2250 | 675 | 14,3 | 0.5 | 199,00 € |

|

| D-F3 6 | 1/4 | 6 | 3100 | 930 | 20 | 0.5 | 248,00 € |

|

| D-F3 8 | 5/16 | 8 | 5200 | 1560 | 35.7 | 0.5 | 430,00 € |

|

| D-F3 10 | 3/8 | 10 | 7750 | 2325 | 46.3 | 0.5 | 540,00 € |

|

| D-F3 12 | 1/2 | 12 | 11500 | 3450 | 80 | 0.5 | 990,00 € |

|

Strength = breaking strength of the rope in ideal circumstances

WLL= the maximum working load designed by the manufacturer

1 daN = 10 N, about 1 kg

Elongation (stretch) = relative change of the length measured between "pre-tension" (10% of breaking strength) and "working tension" (30% of breaking strength)

Mastrant are braided ropes with twisted cores. All have cover from Polyester

Dyneema® is brand of DSM for Ultra-High Molecular Weight Polyethylene

Mastrant-M ropes use new Dyneema® Max Technology fibres DM20

We supply any length of the rope, the reels are discounted. Standard assortments are reels with 100m and 200m, several types also in 31m and 500m.

Description of rope product lines

Mastrant CLASSIC (colour variants Mastrant-P, Mastrant-C, Mastrant-R, Mastrant-Q and reflective Mastrant-S)

Rope Mastrant Classic is a guy rope optimized for guying with respect to maximized "performance/price" ratio. This excellent rope offers very good strength, low elongation, high UV and humidity resistance. It has low weight, great abrasion resistance, great durability and is nonconductive (no effect whatsoever on your antenna). Moreover, in contrast to ropes made from aramid fibres (Kevlar, Vectran, Technora, Twaron), it has knot strength about 60 %.

- Construction: Braided rope with twisted cores

- Core (Mastrant P and C): Polyester, parallel-arranged twisted cores

- Core (Mastrant Q, S and C 6mm): Polyester & Polypropylene, parallel-arranged twisted cores

- Cover: Polyester 12 or 16 (depending on the diameter)

- Safe temperature: -110 °C (-166 °F) to 120 °C (248 °F)

Mastrant-M (Mastrant PREMIUM)

MASTRANT-M is the choice for those who require a thinner rope with high performance at an affordable price. Very high strength, negligible elongation, very low weight, and great abrasion resistance - are all attributes that make this rope a perfect for guying. It is a highly durable rope with an outstanding performance-to-price ratio. Of course is nonconductive (no effect whatsoever on your antenna).

MASTRANT-M ropes using new Dyneema® Max Technology (by DSM) maximizes the scope of the world’s strongest fiber. Mastrant® is pioneering the use of high performance synthetic rope in permanently loaded applications. Designed specifically for mooring production facilities in deep waters, DSM’s new ‘ultra high strength at low weight’ Dyneema® DM20 fiber delivers unrivalled rope strength, stiffness, durability and longevity.

Laboratory tests demonstrate that ropes made from DM20 fiber retain the property characteristics of Dyneema®, even under long-term high tensions. Critical behavioral qualities, such as high static strength and stiffness, exceptional abrasion, fatigue and creep resistance enable a smaller, lighter rope to deliver improved performance and operational benefits. Dyneema® Max Technology performs significantly better than SK78 on creep and thus is another step change versus all other HMPE (high-modulus polyethylene). At the same time it keeps the good properties of Dyneema® fiber, which are appreciated by many users. The breakthrough product now offers all the benefits of ropes made with Dyneema® also to the markets of permanently loaded applications like guying of towers, masts and antennas.

- Construction: Double braided rope

- Core: 100% Dyneema DM20, parallel-arranged twisted cores (diameters 1 to 3 mm), braided (4 mm and up)

- Inner cover: Polyester staple (only on ropes with diameters from 6 mm and up)

- Outer cover: Polyester 12, 16, 24 or 40 (depending on the diameter)

- Safe temperature: -110 °C (-166 °F) to 90 °C (194 °F)

HMPE ropes D-F3

High Modulus PolyEthylene rope is one of the strongest, most durable and innovative ropes on the market today. The rope is made of high-modulus polyethylene. The HMPE ropes are impregnated with durable coating to reduce abrasion and extend the service life. The extraordinary features and extreme strength of HMPE ropes is a reason for using it as frequent substitute to steel wire/steel ropes. The HMPE ropes go through a special heat and UV resistance treatment. They have an extremely low friction coefficient and highly reduce an operation costs. Additionally, they offer much safer handling solution compared to a standard steel ropes.

The rope surface is furnished with a special protective finish which endows the rope with unusual abrasion resistance and stability even when exposed to UV radiation. Considering its extraordinary properties, the rope is the choice for the extreme projects.

HMPE ropes slightly stretch if they are in great tension for a long time. This property is called creep. This is not a problem for many applications: regular (e.g., once every 6 months) tightening does not matter, or the ropes are not permanently stressed (for example, masts where there is no permanently high tension, but only during strong winds).

- Construction: 12-strand braided heat set rope

- Material: 100% HMPE superior (Nexsteel), special surface finish

- Safe temperature: -110 °C (-166 °F) to 90 °C (194 °F)

Mastrant-D (discontinued)

- Construction: Double braided rope

- Core: 100% Dyneema SK75, braided

- Inner cover: Polyester staple (only on ropes with diameters from 6 mm and up)

- Outer cover: Polyester 12, 16, 24 or 40 (depending on the diam.)

- Safe temperature: -110 °C (-166 °F) to 90 °C (194 °F)

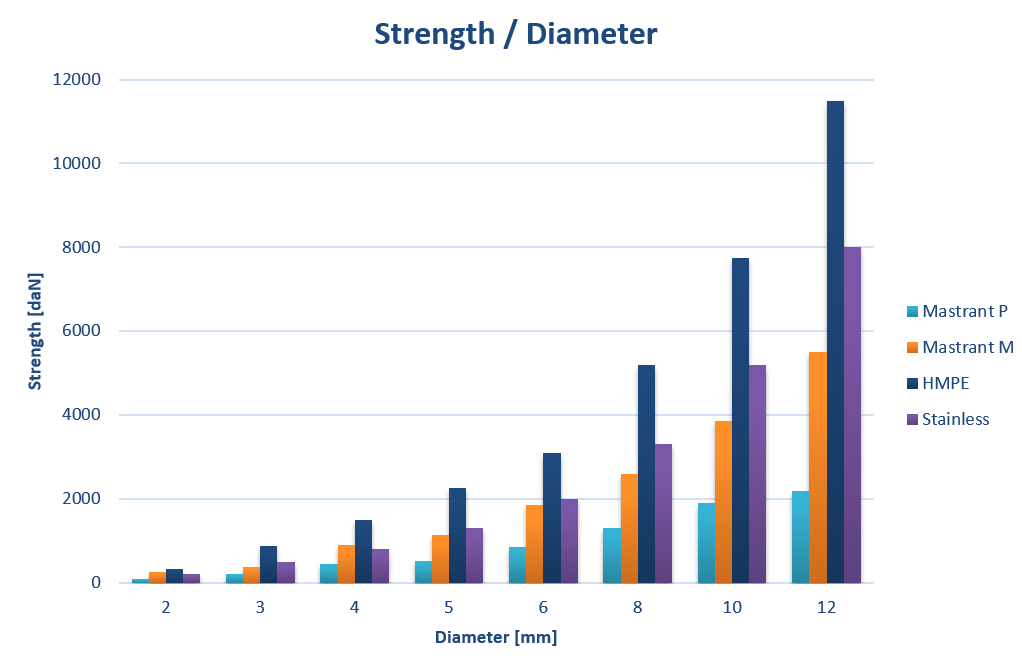

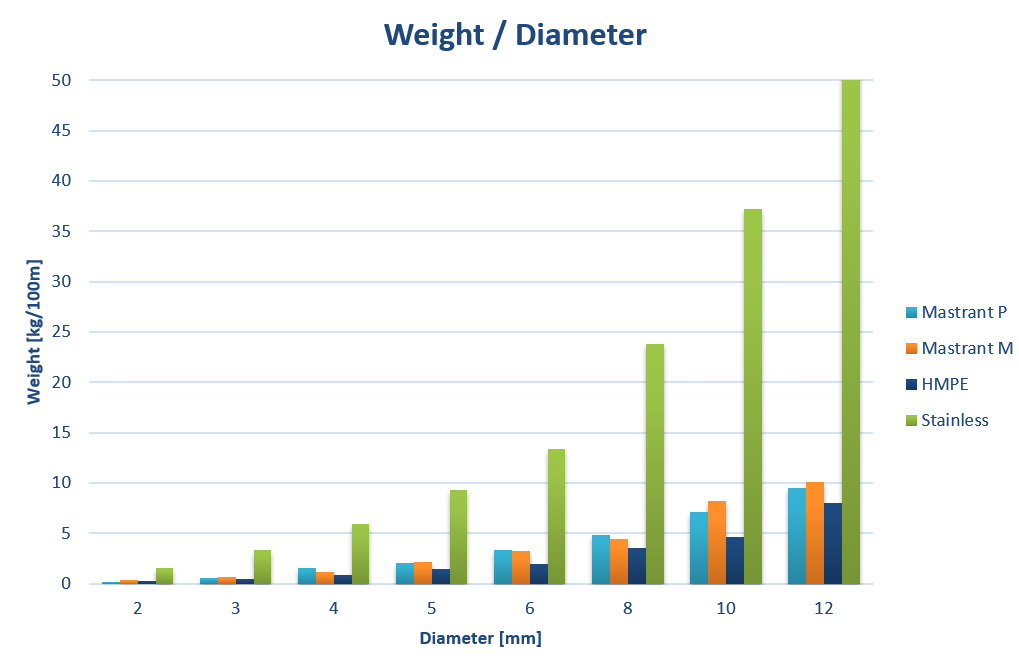

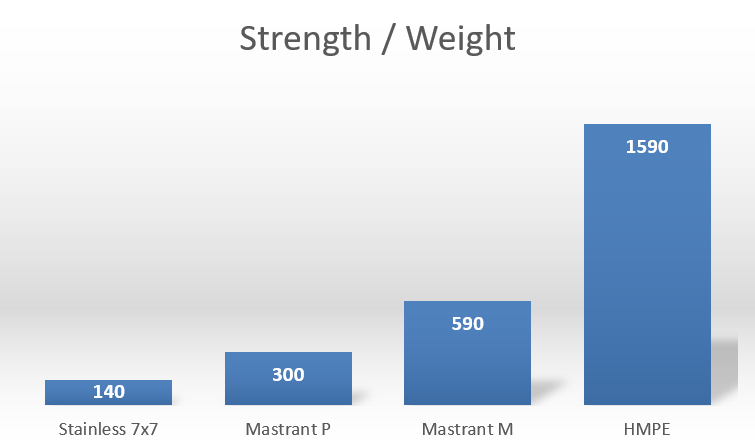

Comparison of Mastrant ropes features

Our direct competitor: hamrope